|

Caring for expensive portable equipment is often neglected. The result is damage, or lost equipment. The emergency response team for whom these were made needed a way to get up to a dozen radios (walkie-talkie type) on-site in a variety of locations, but the specifics were unclear at the time of the initial consultation. This first meeting was spent drawing on a whiteboard and discussing different requirements. The Radio Bags seen below are the product of a prototype process. When the original project was negotiated, it was agreed that an initial prototype would be produced - and later used as a spare. The first pair of photos shows the prototype - in use. Once the prototype was produced and tested, the necessary improvements would be specified, and the remaining three units were then to be manufactured to the final specification.

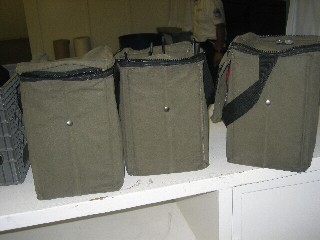

The photos immediately below show the three final bags. The photo below right shows how the bags have been compartmented to allow protection for each radio from the others. The thinner divider in each quadrant is to protect the microphone and the radio from each other during transportation.

The photo below left shows one of the radio bags with the interior partitions removed. The bag was designed so that the interior partitions could be installed and taken out by fastening with industrial strength snaps. Otherwise, the assembly operation would have been overly complicated. All of the cloth used in the bags is fireproofed canvas (military surplus). The outside and main partitions are filled with a 1/2" thick closed cell foam which provides both protection for the radios, and makes the assembled bag rigid. The bottoms of the bags (not shown) are lined with tempered hardboard, to which the external feet are riveted.

|

|

|